Company Profile

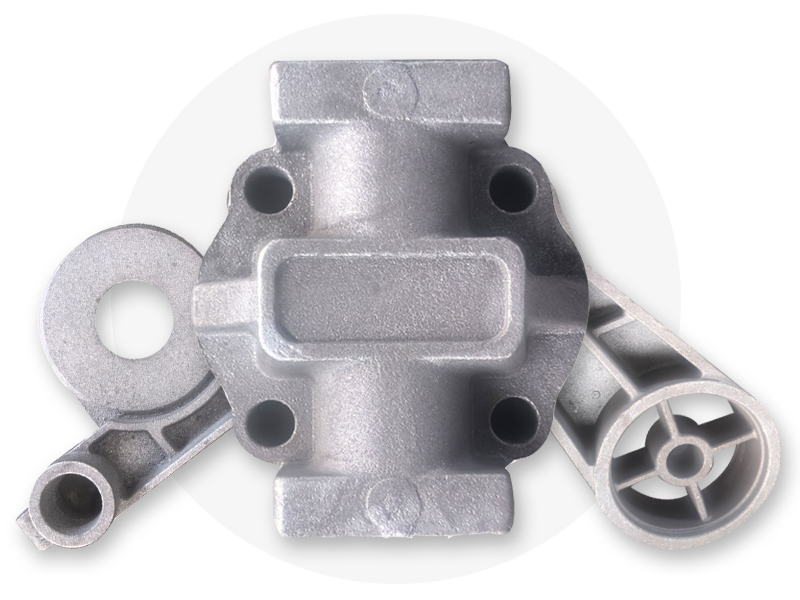

Laizhou Dingtai Machinery Co., Ltd. is located in Yantai, an important port city in the Bohai Rim region, and Shentang Industrial Park, Hutouya Town, Laizhou City, Yantai City, Shandong Province. The company covers an area of more than 40 acres and has a casting capacity of 7300 tons. Our company mainly provides: The main fields of ductile iron and gray iron castings include construction machinery accessories, agricultural machinery accessories, etc. In recent years, the company has passed the ISO9001 quality management system certification, RoHs recognition. Certificate, and has a number of practical patents, the company's ductile iron, gray iron casting brand: ductile iron brand 400-18,450-10,500-7,600-3,700-2; Grey iron brand 150.200.250.300.350. The company has its own laboratory.

Company established in 2000

The company covers an area of more than 40 acres

Casting capacity 7300 tons

Our Advantage

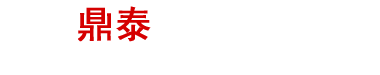

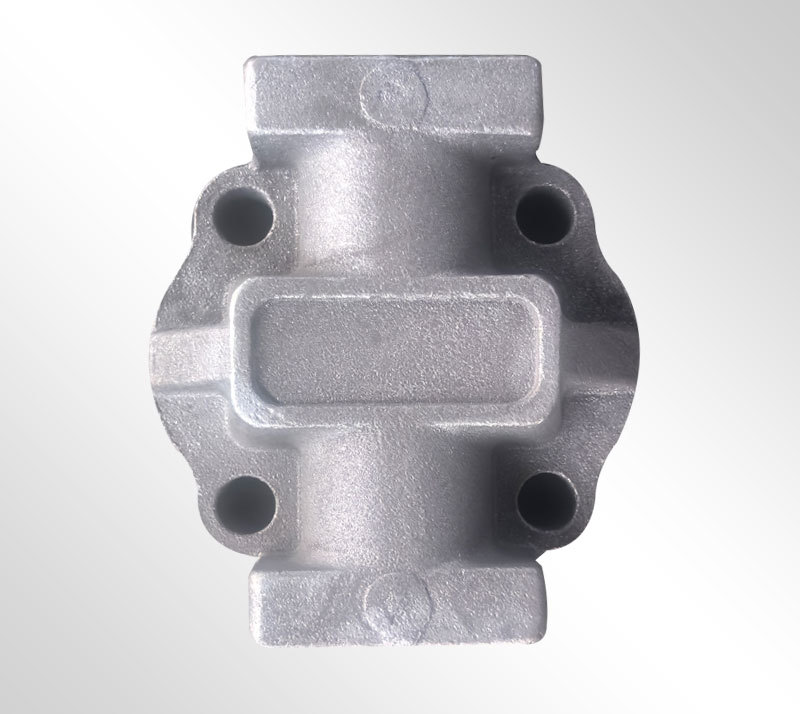

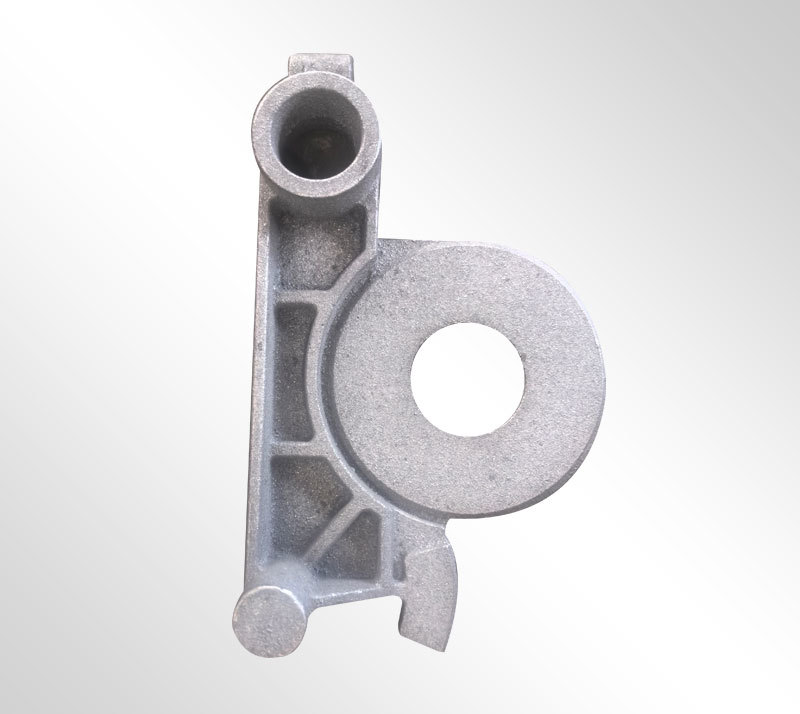

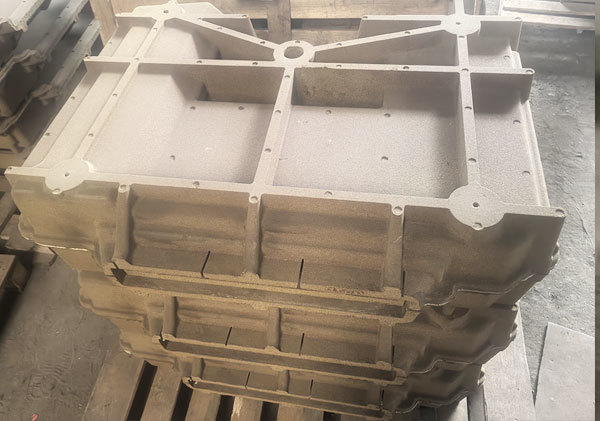

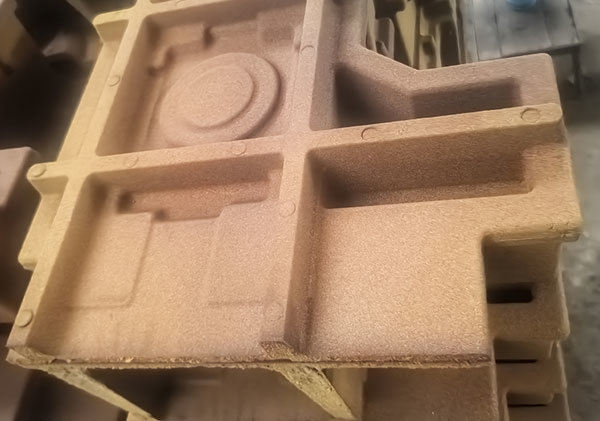

Excellent casting process

We use high-quality silica sol casting technology to improve product accuracy and reduce customer's processing costs.

Perfection of quality control system

We have modern workshop equipment, advanced production technology, is committed to the production of high quality industrial products for customers.

Custom Solutions

We can provide professional customized solutions according to customers' drawings and material requirements.

Perfect service

Committed to the establishment of professional technical team, quality team and sales team, dedicated to customer service.

ADVANCED EQUIPMENTS

CERTIFICATIONS

Blog

2025/03/31

Reasons for the generation of white iron castings

The main causes of white iron castings include chemical imbalance, excessive cooling rate, insufficient inoculation treatment, segregation of trace elements, and improper process control.

2025/03/31

What causes shrinkage porosity in ductile iron castings?

The main reason for shrinkage cavities in ductile iron castings is that the liquid and solidification shrinkage during alloy solidification are not effectively compensated, superimposed on improper casting structure, component design, or process control.

2025/03/31

What causes the loose structure of ductile iron castings?

Loose structure in ductile iron castings is one of the common defects in the casting process. Its formation is complex and involves multiple stages.